Financed by the Marie-Curie International Training Network, the school finished its work in December 2015 after four years. Focused on the development of innovative and sustainable cellulosic packaging, NewGenPack has achieved some interesting results in various research projects and scientific and technological approaches and has promoted training of young researchers.

Launched in 2011, the NewGenPack project (Generation of Cellulose Fibre Based Packaging Materials for Sustainability) involved eight universities, three research centres and six companies, all from Europe. The original idea to launch a cellulosic packaging project aimed at finding innovative solutions and training young researchers so that they could develop interdisciplinary skills to use for the future development of cellulosic packaging was successful.

Coming from different countries, ten young researchers (ESRs= Early Stage Researchers) worked in some of the most prestigious universities and research centres during those four years. They focused their studies on aspects linked to functional barriers and active packaging. Most of the recruited researchers followed a PhD course and, at the same time, attended specific workshops organised by the network. The fact that the various organisations specialise in different subjects enabled researchers to access highly differentiated training starting from training on paper all the way to the chemical functionalization of fibres and their use in active packaging. A further interesting part of this programme was the short-term placements (one to four weeks) that most students took advantage of. This meant that they could work in the laboratories of the other organisations to carry out specific activities they could not perform in the laboratories they were working in. ESRs were therefore able to obtain better results from their own research projects. The placements also strengthened the links between the various organisations. The benefits of this initiative will be felt in the future. Moreover, the publication of scientific work, contacts with companies and suggestions for other projects were some of the outcomes reached by these partnerships. As well as ESRs, two senior researchers worked at participating companies and, at the same time, followed the project’s training courses.

Contributing to innovation in the sustainable cellulosic packaging was the project’s guideline. However, apart from the high-level scientific results, the main aspect was the development of a new generation of researchers from different countries who acquired direct experience in this sector thanks to the Marie Curie European funding. Not only does this programme focus on some aspects of research but it also focuses on interdisciplinary training by creating European networks with universities, research centres and private businesses.

These are some examples of the results achieved by the researchers

Barrier properties

At the Danish Technical University, John Trifol managed to extract cellulosic nanofibres from sisal. He subsequently acetylated them with simple process that could easily be adopted on a large scale. Fibres were then introduced in the PLA thus reducing permeability to oxygen by 90% and to steam by 76% as opposed to the untreated control sample. Thanks to the composite material thus developed, the release of carvacrol (an essential oil) in active packaging can be controlled.

Working at the University of Bologna, Caglar Mericer analysed the effects of permeability to steam and oxygen on films of carboxymethyl cellulose (CMC) and microfibrillated nanocellulose (MFC). A fully biodegradable multi-layered film based on PLA-MFC was prepared. The film showed a reduction in permeability to oxygen in low humidity conditions by a factor of 100.

Antimicrobial properties

Seema Saini, who worked at the Grenoble Institute of Technology (FR), showed that cellulose nanofibers can be chemically functionalised in an aqueous environment with different active principles. By grafting NFC with cyclodextrin, the release of active principles can be controlled. NFC-nisin is a particularly promising substance for the packaging of food. Active surfaces were prepared by grafting benzylpenicillin onto nanofibers. In this case, the antibiotic is not released but it acts through direct contact. This solution was adopted with a flexographic paint that can by applied by printing and could be extremely interesting for single-use medical packaging used in hospitals by preventing contamination of pathogens like S. aureus.

Qihao Tan, who worked at the Szczecin University of Technology in Poland, confirmed that some essential oils (Cinnamon oil e Argy wormwood oil) have high anti-bacterial properties against a wide range of microorganisms and can be prepared in a stable pre-emulsion. Over time, stability can be increased to ten weeks with triglycerides. The introduction of these oils in coating formulations has shown that they are effective anti-bacterial agents. However, the smell issue that could affect the organoleptic properties if used in active packaging applications has still to be solved.

Joana Mendes at Innovhub-SSI

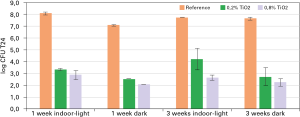

At Innovhub-SSI, Joana Mendes explored the use of metallic nanoparticles to obtain antibacterial papers. Photoactivated nanoparticles of titanium dioxide (Ti02) are very effective on a wide range of gram-positive and gram-negative bacteria. Titanium dioxide was used on fibres and nanocellulose with different techniques enabling its use both directly, by dip-coating on hydrophilic fibres, and through rod coating techniques, after inclusion in microfibrillated nanocellulose (MFC). Titanium dioxide was directly linked to MFC by using the different electrical charge with relatively low retention (20%) and employing deposition techniques with polyelectrolytes (Layer-by-layer assembly) thus reaching a 90% retention on fibres with three layers of material. Photoactivation with solar light of a highly hydrophilic white kraft paper with virgin fibres and titanium dioxide has shown a very high antibacterial activity amount to around 5 logarithms of reduction in the number of bacteria. This figure is higher than the 99.9% reduction in bacterial growth compared with paper without active titanium dioxide. Antibacterial activity remained stable for three weeks both in dark conditions and with low lighting (indoor light) as highlighted by the data in figure 1. Concentrations of titanium dioxide amounting to 0.2g/g, sufficient to obtain good antibacterial activity, did not show negative effects on the degree of polymerisation of cellulose. However, active nanoparticles of zinc (ZnO) were successfully included in a flexographic paint used to prepare packaging that can prevent microbial contamination in hospital settings. Notwithstanding the limitations when changing the formulation of the paint used in the industrial trial, the demonstrator of the Safebox project showed bacteriostatic activity with S. aureus. However, in order to achieve greater antibacterial effect, a formulation that can contain higher concentration of ZnO without modifying the physical and mechanic parameters of the paint ought to be developed.

More informazione…

http://ec.europa.eu/environment/circular-economy

http://www.cepi.org/EPW

http://www.cepi.org/EPW