by Daniele Bussini – Innovhub-Papper Division

The European project, which was launched in Milan in 2012 and is coordinated by Innovhub Paper Division, is about to end after two years of fruitful work and exchange of ideas and opinions on the most important scientific issues related to the recycling of paper and paper packaging thanks to the support of professional associations, companies and stakeholders.

Within the general framework of the improvement of the quality of recycled paper and the importance of sustainability of the same recycling activity, the work done has been carried out in several directions and pursued various objectives, including the following:

- development of a European laboratory method to evaluate the recyclability of paper-based packaging with scores based on evaluation results;

- Life Cycle Assessment studies focussed on product design and the impact of the solutions and components used on the recyclability of the same product;

- analysis of different collection systems and solutions in several European regions, as well as of the relation with the quality of the recycling paper obtained;

- publication of a position paper concerning the policies and regulations on recycling issues, as the result of a far-reaching survey among the main players involved.

The results will be presented on the occasion of a dedicated seminar, which will be held at the headquarters of the Regional Authorities of Lombardy in Milan on 7th October 2014, while the project final results and conclusions will he illustrated at the Final Conference of the EcoPaperLoop project, which will take place on 2nd December 2014 in Cracow, Poland.

A European method for the analysis of recyclability

Over the past two years project partners have agreed upon and finalized a method for the analysis of recyclability and the evaluation of results, capable of simulating the most important aspects of the recycling of paper packages in the paper sector.

The experience of the laboratories of the Darmstadt Polytechnic in Germany and the Innovhub Paper Division have made it possible to develop a method, which based on already existing national methods could on the one hand evaluate significant product quantities and on the other hand comply with other European evaluation methods and systems currently available, like the Erpc and Ingede methods that are currently used also in the EU Ecolabel schemes.

The method was validated and is currently applied in the four European labs participating in the project, i.e. in Italy, Germany, Slovenia and Hungary. After acquiring the necessary equipment and organizing a training course on the testing procedure for the workers involved, the method was validated through a Round Robin Test. Three types of different products were tested in the various labs for the statistical evaluation of the reproducibility of results.

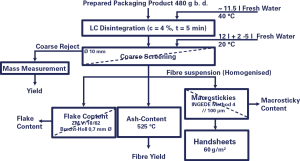

In the test was used 480 g dry material cut in portions of about 10×10 cm each. Pulping is carried out with a standard piece of equipment built at the Darmstadt Polytechnic with 4% consistency and for five minutes. The short pulping time makes it possible to realistically evaluate the behaviour of the material in terms of separation of the fibres, residual flocks of unseparated fibres, i.e. Flake Content, and coarse waste fractions (i.e. the so called Coarse Reject).

The pulp then undergoes a coarse screening by means of a screen with holes as large as 10 mm in diameter. Fibre suspension, i.e. the fraction smaller than 10 mm in diameter passing through the holes is used for further analyses, while the reject, which is made up of non-paper components or large paper fragments that cannot be pulped, is weighed and expressed in percentage against the starting quantity.

Fibre suspension is used for the measurement of flocks, i.e. small plastic impurities or lumps of unseparated fibres present in the suspension. The separation of flocks occurs by means of a mechanical screen on a 0.7 mm plate with holes.

Always using fibre suspension it is also possible to measure the particles of insoluble adhesives, so-called macrostickies, which are separated from the fibrous fraction by means of a screening stage on 100 micron large openings. Adhesive particles are analysed following a proper method and quantified with the image analysis. The value of macrostickies smaller than 2000 micron in diameter is registered, as this is the fraction that is most difficult to remove in standard pulp cleaning installations and can potentially damage the recycled paper manufacturing process.

The assessment furthermore concerns the overall yield of the recycling process as available material after the coarse screening, as well as the fibre yield, i.e. the fraction of cellulose fibres recovered net of ash content.