A research study developed and patented by the Milan Polytechnic University shows that filters in corrugated cardboard, which have undergone a proper antibacterial treatment, can purify the air we breathe.

A brilliant idea both for its scientific effectiveness and for the aesthetics: in order to fight against two of the main perils present in the air we breathe, i.e. bacteria and fine powders hiding in closed environments like houses and offices, a group of researchers of the Milan Polytechnic University of Milan, collaborating with Ghelfi ondulati, has developed and patented a new technology for the creation of filters that should be built in air conditioning installations, fan-coils and scooping cabinets capable of reducing the bacterial load and solid particles. NextMaterials is a spin-off member to the Interuniversity Consortium for Science and Material Technology (Consorzio Interuniversitario per la Scienza e Tecnologia dei Materiali, Instm), has applied this technology to objects in corrugated cardboard. This is a material that provides for high environmental sustainability, as thanks to the antibacterial treatment and the use of computer fans allowing for air circulation it serves as a filter capable of depolluting environments. Daniele Pezzoli, of NextMaterials and Instm, describes the functioning of antibacterial filters for air purification and the context where this invention should be framed.

Mr. Pezzoli says that «the problem of air quality in closed environments is very important, as many of us are still convinced, although in a rather naive way, that the air breathed in our home or office is clean, while evidence shows the presence of chemical, physical or biological pollutants in internal air or air in confined environments, whereby the same pollutants are absent or seldom present in outside air». Mr. Pezzoli explains that «the level of pollution in a closed environment can be due both from outside particles accumulating inside, and to internal sources (i.e. people, animals, smoke, fabrics, carpets, furniture) that generate chemical particles or substances». «Consumption products also contribute to pollution: let us think for instance about detergents, insecticides and kitchen-related products. One should furthermore consider the diffusion of building measures, which, together with the use of air conditioners and dehumidifiers, contribute to maintain temperatures low during the summer and high during the winter, thereby reducing air exchange between outside and inside environments. As a consequence, particles, chemicals or micro-organisms tend to accumulate inside a room and can also reach very high concentrations», with consequences on people’s health. The need for systems for the purification of air from polluting substances and biological agents has therefore increased over the years.

Fighting against moulds and bacteria: a cardboard filter

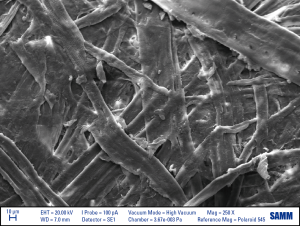

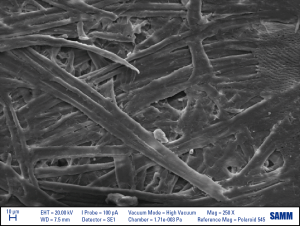

Hepa (High Efficiency Particulate Air) is the filter par excellence for the purification from biological agents, which is capable of removing moulds and bacteria almost entirely. Up to not long ago, it was only used in places, which needed to be sterile and extremely clean (clean rooms, chambers, intensive care units in hospitals or tissue culture hoods where the cultured cells must be kept away from bacteria). Yet, in recent years these filters have been applied also to domestic technology, specifically to dehumidifiers or vacuum cleaner, in order to prevent that bacteria are contained in the outflowing air. Besides high efficiency, also the disadvantages of this type of filter should also be considered, i.e. load reductions, high energy consumption, increased noise and high costs (due to the need to replace filters). It is here that the product developed with Ghelfi Ondulati FiltriNext, i.e. Tantibacterial filters in corrugated cardboard, finds its proper location. The advantages of corrugated cardboard are well known, especially to experts in the field: low production costs, completely recycled and recycling material, limited load reductions (low indirect costs), as well as ease of treatment. And yet, the most surprising aspect is that untreated corrugated cardboard filters, which do not have antibacterial properties per se, can reduce 77% of bacteria after 90 cycles of air circulation, thereby providing for the mechanical trapping of bacteria. This natural result was further enhanced through isopropylic acid treatment and a specific antibacterial treatment: «Cardboard filters have been made functional by means of an atoxic natural treatment based on the use of a polymer, which was developed and patented by the Milan Polytechnic University. After treatment, the reduction of bacterial load is further increased and can be up to 90% after 70 air circulation cycles without increasing the losses due to pressure load (and thus without reducing the ventilation effect of the filter). This treatment provides for high antibacterial activity on filter surface, which is comparable to that of silver salts. Bacterial growth can be inhibited on the filter and the risk for the blocked bacteria to circulate again is thus avoided».

Applications and advantages

The FiltriNext filters have manifold applications: «They can be applied to already existing heating, air conditioning and ventilation systems, as well as air inflow grids. The filters have furthermore been already tested, with very good results, inside household fridges or shops and supermarkets scooping cabinets. The tests showed a reduction of the bacterial load also inside refrigerators; furthermore, low-consumption and low-noise purifiers can be ad hoc developed». Besides their properties in terms of fine powders and bacterial load reduction, the main advantages offered by the FiltriNext filters are mainly related to the features of corrugated cardboard, which is a recycled and recycling material and has therefore limited costs. These features contribute to make the filters noiseless thanks to their limited loss of pressure load, as well as atoxic, recycling and suitable to be produced in any form and size».

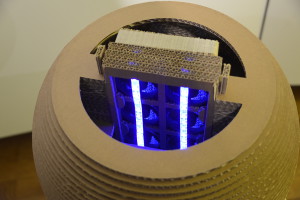

CactusNext: between technology and design

Thanks to the integration of various technologies, the CactusNext purifiers in the shapes of cactuses (design by Carolina Chini) and spheres are objects made of corrugated cardboard, which act as purifiers thanks to their (FiltriNext) filters inside and the fans, which provide for air circulation inside the object, thereby purifying it. And they are also beautiful: «they are an alternative way to reduce fine powders and bacteria in closed environments with an innovative design, they are easy to assemble and disassemble, noiseless and sustainable». CactusNext features a body in corrugated cardboard and provides for the photocatalytic and antibacterial treatment of the filter; it is equipped with 12 VDc fans, 60 mA, 0,72 W, noise: 120 dB and 220 VAC-12 VDC external plug transformer, 2,000 mA. Besides the CactusNext purifiers and the CactusScent fragrance dispensers, NextMaterials has created 3D art reproductions (design by Designamente) ad hoc for the 2013 Milan Furniture Fair (Salone del Mobile 2013) in the shapes of the beautiful Aphrodite of Milos (Venus de Milo) and the Terracotta Warrior in natural size.