In traditional activated sludge plants, biomass form flocks are kept suspended in wastewater and then separated from treated water in a settler; most biomass is re-circulated to the biological tanks, the excess is extracted and sent to sludge treatment.

Luigi Falletti, University of Padova

This technique is the most widespread and well known in the world to treat biodegradable municipal and industrial wastewater (including paper mill wastewater); but it has also disadvantages: it requires large tanks, and pollutant removal efficiency is strongly affected by sludge settleability.

In moving bed biofilm reactors (MBBR) biomass grows as biofilm on plastic carriers that move freely into wastewater; tanks are similar to activated sludge reactors, and they have screens or sieves to avoid carriers’ loss; aerated reactors are mixed by aeration itself, while anoxic and anaerobic reactors are mixed mechanically. MBBR can be classified into two categories:

- pure biofilm reactors: biomass grows only on carriers without suspended sludge and without sludge recirculation;

- hybrid reactors: in the same tank biomass grows both as biofilm on carriers and as suspended sludge; part of sludge is re-circulated.

MBBR have several advantages if compared to traditional activated sludge tanks and to fixed biofilm reactors (trickling filters, submerged biofilters):

-biofilm has high specific activity, therefore high pollutant removal efficiencies can be achieved with smaller tanks than the ones required by activated sludge;

-in plants with a series of MBBR a specialized biomass grows in each tank;

–risk of clogging with MBBR is much lower than with fixed biofilm reactors, no backwashing is required since biofilm in excess is detached from carriers by reactor turbulence itself, and can be separated from treated water by settling or flotation;

-this technology is very flexible in plant conduction: in pure biofilm reactors, the filling degree can be varied according to process requirements, in hybrid reactors also sludge recirculation rate can be varied.

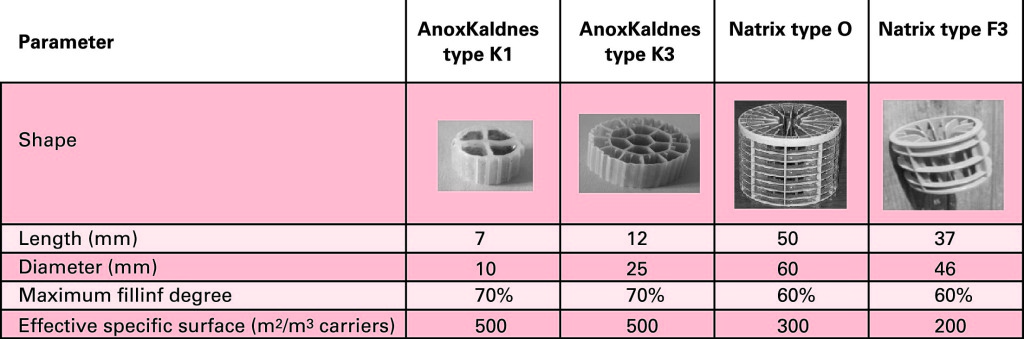

Carriers in use

Several kinds of carriers are used in MBBR: they can be classified according to material, shape, porosity, dimensions, specific surface. Among these characteristics, specific surface is particularly important: it represents the surface which is available for biofilm growth pr. cubic meter carriers. For each kind of carrier, part of specific surface is protected and the remaining part is external; biofilm grows almost only on protected surface, because external surface is exposed to collisions among carriers and against reactor walls; so the effective specific surface is only a protected one. First biofilm growth on carriers requires some weeks; bacteria produce surfactant substances, so some scum can be observed during the first days in plant starting [1, 2, 3, 4].

Carriers can be introduced in MBBR in variable amounts: filling degree is the ratio between the carriers’ apparent volume and the tank volume, and it can vary from zero to a maximum value that depends on the carriers’ characteristics. With higher filling degree, total biofilm surface and pollutant removal efficiency increase, but higher mixing energy is required. The most widespread carriers are made of polyethylene or polypropylene, their density is about 0.95, and usual filling degrees’ range is 30–60%; the characteristics of some kinds of carriers produced by AnoxKaldnesTM Company are listed in table 1.

Possible configurations

MBBR can be applied for wastewater treatment in several plant configurations:

1. pure MBBR biofilm before an activated sludge plant: this solution is common for concentrated wastewater treatment;

2.upgrading of overloaded activated sludge plants by conversion into hybrid MBBR;

3.tertiary biological treatment by pure biofilm MBBR after an activated sludge plant;

4.complete biological treatment by series of MBBR: pre-denitrification, oxidation, nitrification, post-denitrification.

MBBR have been and are applied to treat municipal wastewater [5, 6, 7, 8, 9] and industrial wastewater including paper mills [10, 11, 12], winery [13] and dairy [14]. This paper deals with the results of some European full-scale plants with MBBR for paper mill wastewater treatment.

Case studies

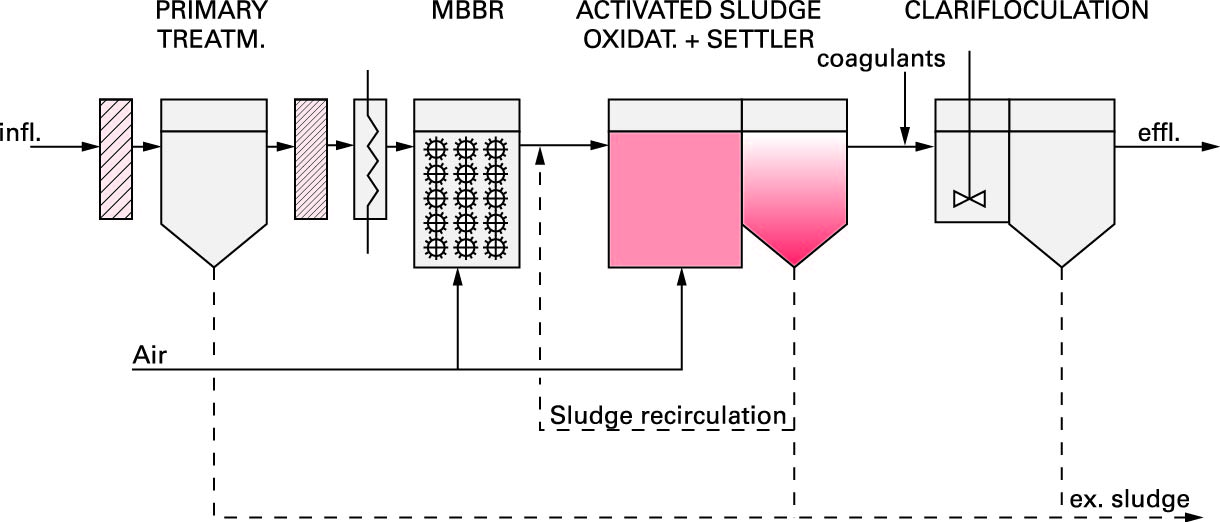

Industry nr. 1 produces about 18.000 m3d-1 wastewater with 2.500–3.500 mg/L COD. The wastewater treatment plant (picture 1) is made of a coarse screen, a primary settler, a fine screen, a cooling system, dosage of nutrients (nitrogen and phosphorus salts), a biological section and a final clarifloculation. The biological section has a first aerated pure biofilm MBBR with 2.500 m3 volume filled with 40% NatrixTM – O carriers, an activated sludge oxidation tank with 7.500 m3 volume and sludge concentration 4-6 kgSSTm-3, and a secondary settler. The plant must remove at least 90% of COD, 99% of BOD5; maximum pollutant concentrations in final effluent are: TSS < 50 mg/L, tot-N < 4.7 mg/L, P < 0.3 mg/L.

On average basis, the plant has treated an effective organic load of 59.000 kgCODd-1, the first MBBR has removed 51% of COD and the following activated sludge oxidation tank has removed 75% of remaining COD; the whole plant has removed 90% COD and has always respected emission limits.

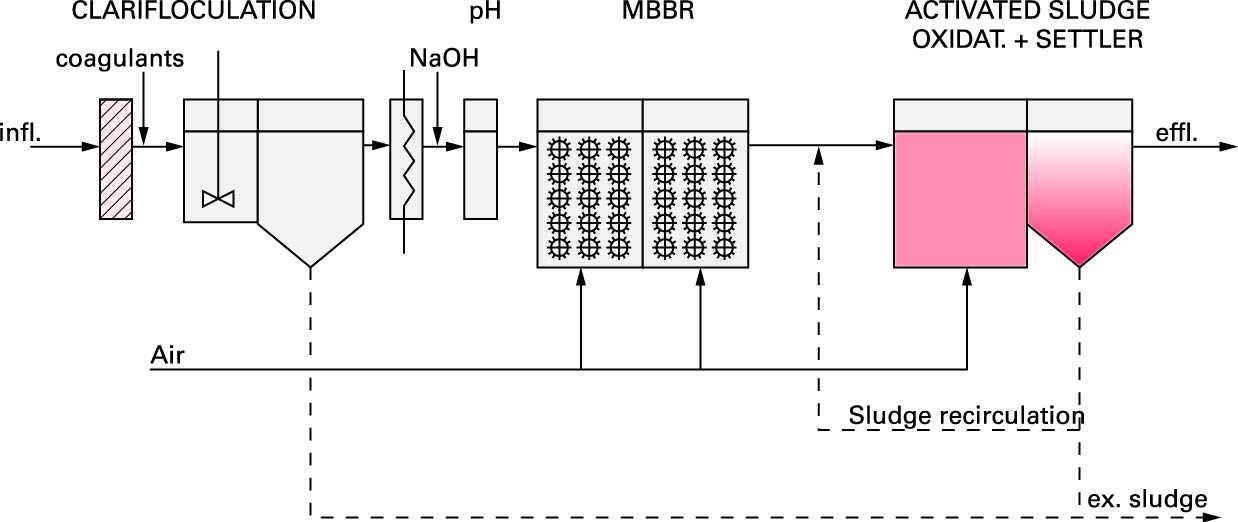

Industry nr. 2 produces about 18.000 m3d-1 wastewater with 2.000-2.500 mg/L COD. The wastewater treatment plant (picture 2) is made of a cooling system, dosage of nutrients (nitrogen and phosphorus salts), pH correction and a biological section. The biological section is made of two serial aerated pure biofilm MBBR with 1.900 m3 volume each filled with 20% NatrixTM – O carriers, an activated sludge oxidation tank with 10.000 m3 volume and sludge concentration 2-5 kgSSTm-3, and a final settler. The plant must remove at least 70% COD, 50% total nitrogen and 50% total phosphorus; moreover, maximum TSS concentration in final effluent is 30 mg/L.

On average basis, the plant has treated an effective organic load of 38.000 kgCODd-1, the two MBBR have removed 35% COD, the whole plant has removed 70% COD and has always respected emission limits.

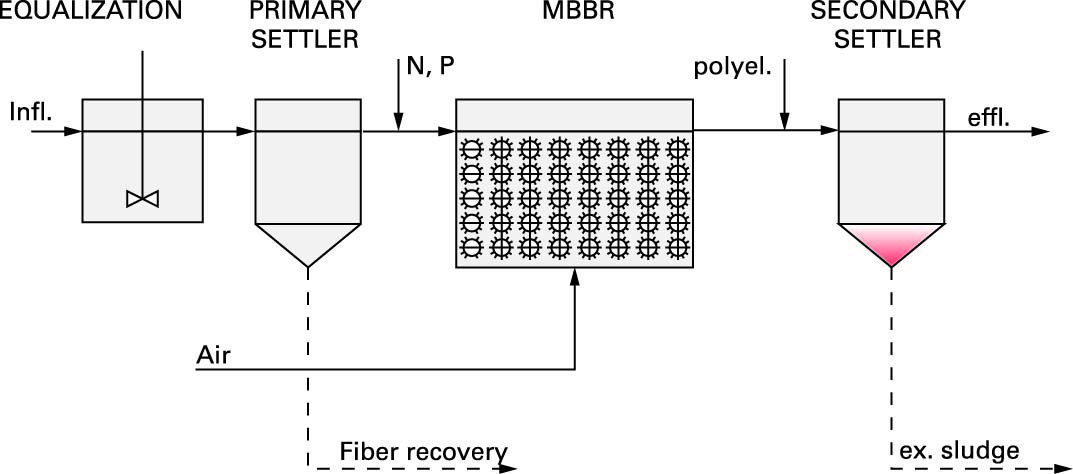

Industry nr. 3 produces 2.800 m3d-1 wastewater 800-1.300 mg/L COD. The wastewater treatment plant (picture 3) is made of an equalization tank with 600 m3 volume, a primary settler (with fiber recovery), dosage of nutrients (nitrogen and phosphorus salts) and a biological section. The biological section is made of a pure biofilm aerated MBBR with 500 m3 volume filled with 68% AnoxKaldnesTM – K1 carriers, and a secondary settler with polyelectrolyte dosage. Maximum pollutant concentrations in final effluent are: TSS < 35 mg/L, COD < 160 mg/L, BOD5< 40 mg/L.

On average basis, the biological section has treated an effective organic load of 2.660 kgCODd-1, and has removed 90% COD; the final effluent has always respected emission limits.

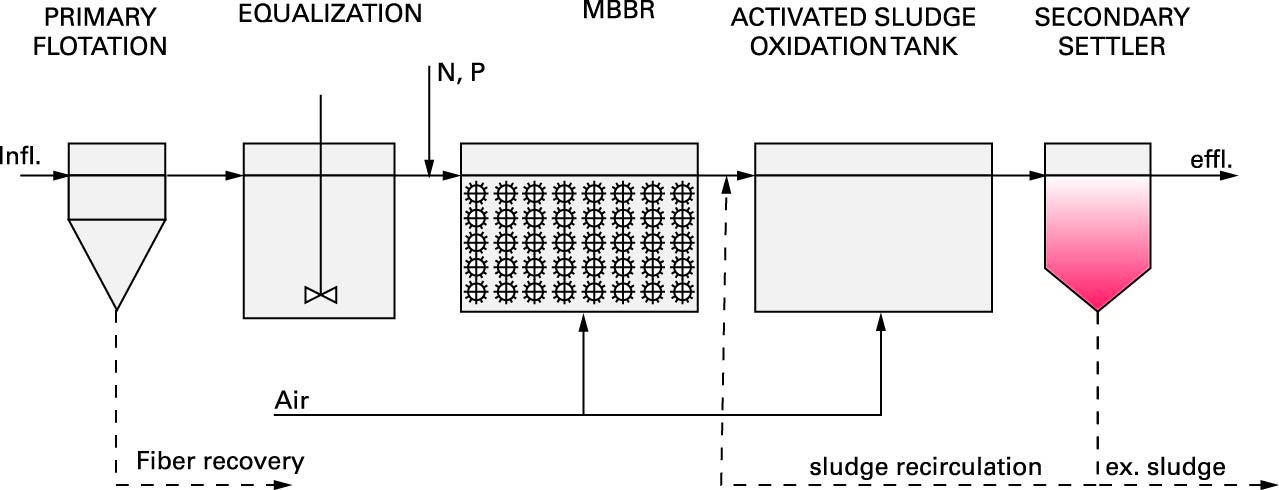

Industry nr. 4 produces about 7.200 m3d-1 wastewater with 2.000–3.500 mg/L COD. The wastewater treatment plant (picture 4) is made of a primary flotation tank (with fiber recovery), an equalization tank with 1.000 m3 volume, nutrient dosage (nitrogen and phosphorus salts) and a biological section. The biological section is made of a first pure biofilm aerated MBBR with 1400 m3 volume filled with 70% AnoxKaldnesTM – K3 carriers (which is the maximum filling degree), an activated sludge oxidation tank with 3.000 m3 volume and a secondary settler. Final effluent must respect maximum pollutant concentration limits: TSS < 35 mg/L, COD < 160 mg/L, BOD5< 40 mg/L.

On average basis, the biological section has treated an effective organic load of 17000 kgCODd-1; the MBBR tank has removed 75% COD, the whole biological section has removed 96% COD and the final effluent has always respected emission limits.

Conclusions

Results reported in this paper show that MBBR are a suitable technology to treat paper mill industry wastewater with high organic substance removal efficiency. They can be applied with several plant configurations; in general, for paper mill wastewater, plants are made of primary treatments (sedimentation, flotation, often also equalization), a first pure biofilm aerated MBBR that removes part of COD, an oxidation tank which can be an activated sludge reactor or a second MBBR, and final solids’ separation system that can be a settler, a flotation tank or a clarifloculation. As reported in literature, also anaerobic MBBR have been applied to treat paper mill industry wastewater.