A revised catalogue in terms of colours and techniques to highlight the fact that high quality papers and paperboards have once again kept their strong position in a market where quality makes the difference. The central role of R&D’s continuous efforts is therefore confirmed.

They look like fabrics – and in some cases they even have the same feel – but they are papers. However, these are the Plain, Pinstripe and Tweed specialty papers, part of the Savile Row Collection which Fedrigoni has showcased in Italy with a roadshow with a strong emphasis on fashion. This is because fashion, with which Fedrigoni wants to carry on keeping strong links with, is the perfect setting for these papers that look like fabrics.

Starting from Naples at the beginning of May, the roadshow also went to Prato, Milan and Perugia. These turned out to be four opportunities to meet the potential users of these new papers: printers, graphic designers, creatives and designers. These events followed those held in Turin and Rome in April where the forthcoming introduction of the Savile Row Collection was announced when a different updated product was launched: the Fedrigoni Century Envelope Catalogue.

Experts in Specialty Papers

The specialty papers manufactured by this Italian company – an expert in fine papers for printing, publishing, labels, binding, packaging and paper products – are also sold abroad. In fact, without including self-adhesive supports, 62% of Fedrigoni’s turnover relates to manufacturing and marketing of specialty papers abroad whereas 38% refers to sales in Italy», states Chiara Medioli, the company’s Marketing Director.

Being able to follow current trends in this sector and meeting different customers’ needs require a solid knowledge of markets that are often very different. As the Director explains, «Trends vary according to the country where a customer is: in Italy and Europe, for instance, customers choose natural rather than coated papers for many jobs involving photographs: museum publications or fashion and furniture catalogues. In the US, however, photographers prefer to use coated papers. When it comes to packaging, many European customers tend to choose textured and natural papers. However, because of their global reach, international luxury brands, such as cosmetic companies, prefer cast coated papers, the ultimate in terms of smoothness and shine».

Created from Innovative Processes

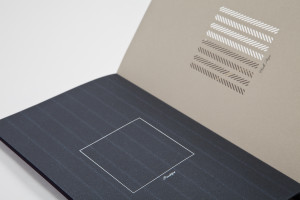

As far as trends are concerned, the Savile Row Collection matches the tastes of a high-level market. The roadshow celebrated the re-introduction of a well-known product that is part of the large range of luxury papers and is manufactured in the Varone factory near Trento. The catalogue has been updated both in terms of colours, with two new nuances – Aubergine and Brown – that follow current men’s fashion trends, and in terms of finishing and technological solutions of their manufacturing process. In particular, the Tweed papers are now characterised by a more subtle and elegant embossing whereas the Pinstripe papers are wet manufactured and are not printed.

However, the most interesting innovation relates to the manufacturing processes of papers in the Savile Row Collection. Thanks to the Group’s continuous R&D, adjustments to manufacturing processes have meant that the final products have greater elasticity and, therefore, are easier to fold. «When we decided to update the range» explains Ms Medoli, «we decided to do it from both an aesthetic point of view by introducing two new colours, and from a technical point of view by improving their folding qualities in particular». The three types of papers, as well as being FSC certified, are made with pure ECF (Elementary Chlorine Free) pulp (60%), cotton fibres (20%) and textile fibres (20%). The addition of long cellulose fibres, that are therefore stronger, give greater strength to the papers».

The use of cotton fibre with cellulose is not something new for the Italian Group. «The paper had already been created with this composition many years ago», specifies Ms Medioli. «This type of paper that imitates fabrics and the use of natural fibres also represents an aesthetic and environmental choice». Furthermore, cotton is not the only natural fibre used in Fedrigoni papers. Hemp, for instance, can be found in other papers. «Percentages vary according to the type of paper and we also use recycled paper and cellulose».

Intended for…

To launch the Collection, ‘sartorial settings’ were deliberately chosen, as in the case of Milan where we used the Rossi tailor’s shop in the city centre. In other cases we used settings that recalled the world of clothes and would therefore remind people of the final users for these papers, like, for instance, fashion houses. Given its strong aesthetic connotations, this paper is usually chosen by final users rather than printers or processing companies».

The sample book contains examples of special manufacturing that enhance the paper by making the most of its characteristics. «We have included samples made with laminating foil and in relief because this is a very compressible paper and holds well dry pulps. We are also showing the single-side effect and how the paper can be worked to have different types of printing that can give an extremely good idea of fabrics, even on very dark backgrounds. Furthermore, this type of paper can be worked with laminating foils or special prints by, for instance, combining four-colour process with flocking. When printing with such special techniques», explains Ms Medioli, «we recommend to use small sizes, mainly 50×70, to be able to keep the register».

Quality and Innovation

The Savile Row Collection is definitely aimed at top-of-the-range domestic and international markets. The Collection is part of the Group’s strategy to manufacture high level and high quality products, the only choices to keep up with a market that is basically going through a period of crisis. «Fedrigoni acts like a witness here because, by manufacturing specialty papers, it is one of the few paper mills with a strong presence on the market» adds Ms Medioli. This choice can also be seen in terms of commitment to R&D. «Each year the Group invests in innovation. Of the 24 series of papers that are on offer, we try to update two or three ranges thus listening to the market. This way we manage to have a range that holds over time, even though our approach is not to change radically and to guarantee continuity at all times». Coming up with ranges of products that are always available whilst taking quality into account is not easy. «This year we have worked on Savile Row and Century. By the end of the year» reveals Fedrigoni’s Marketing Director, «we will have updated our range of pearlescent papers».

Such wide variety of products means that the company has to keep an eye on evolving trends to be able to understand as early as possible what papers will be successful on the international market. From this point of view, «the Fedrigoni strategy has always been that of following customers’ requirements that push us to improve our offer all the time». According to Ms Medioli, over the next few years, more versatile and more technically reliable papers will be required at international level.

One Catalogue, Three Types of Paper

There are three types of papers and paperboards in the Savile Row Collection: the Plain uncoated papers that imitate fabrics and are characterised by a slightly coarse surface. Their grammage is above 140 gr and they are off-machine laminated with natural starches. Papers and paperboards characterised by lines obtained during the manufacturing process by using a special patented technology applied in continuous machine are called Pinstripe. In this case too, off-machine lamination with natural starches is used for grammage above 100 gr. Finally, natural papers and paperboards called Tweed that are off-machine embossed and whose grammage is above 100 gr. They too are off-machine laminated with natural starches.

All three types of paper are FSC certified and made with pure ECF (Elementary Chlorine Free) pulp (60%), cotton fibres (20%) and textile fibres (20%).