by Giuliana Miglierini

The new polymer that exit the development programme represents the disruption of the paradigm, according to Solenis’, as it proved able to provide strength without impacting softness.

Dry strength and softness are two of the main desires of tissue paper makers around the globe. Strength is the result of multiple factors, among which are the type of fibres used (virgin or recycled, long or not) and the chemical bonds keeping the fibres together. On the other side, softness is a peculiar and almost impossible to measure parameter, as it greatly depends upon the perception of the single user. Softness might not be perceived as the same between different persons or different markets. There are different characteristics affecting softness, often in conflict with the ones asked by tissue makers in order to improve dry strength.

Dry strength additives

Dry strength additives are used to improve paper strength under different conditions by assisting the formation of internal bonds between fibres. Typical additives are natural or semi-synthetic polymers like starch or carboxy methyl cellulose, or synthetic ones, such as polyamines, polyamides and polyacrylamides. Dry strength additives are usually water soluble chemicals that are mixed with the pulp in the paper mill, at the wet end of the process. «Also glyoxylated polyacrylamides (GPAM) or enzymes might be used. They all have disadvantages, as fibre can be costly and refining is energy consuming», said Solenis’ Platform launch and Application manager, Tissue and Towel, Angela Knight, during the recent Tissue World Milan 2017. According to Knight, refining also someway damages fibres, as it decreases their ability to generate bulk. «There are many synthetic dry strength aids on the market. They deliver dry strength, but in many case they’ve been found to have an impact on the softness of the tissue», explained Solenis’ representative, while presenting the results obtained with a new type of dry strength additive – Hercobond™7550EU – developed by the company.

Strength without rigidity

The challenge Solenis’ R&D department had to face was how to obtain strength of the tissue paper without rigidity. «First of all, we looked why synthetic and natural dry strength aids give rigidity to the tissue. We looked at the way they form bonds with the fibre and we found that, in most cases, they form very stable and rigid bonds that makes the tissue stiffer», said Mrs. Knight. Starch, for example, starch interacts with the z-direction of the sheet surface, giving rise to an I-beam effect; GPAMs, instead, forms covalent bods. Research scientist Dr. Joseph Mahoney designed a pilot paper machine to test about strength/softness correlation and their impact in stiffness, elongation at break and correlation to creeped sheet. The final goal of the project was to develop a new product able to break the connection between strength gain and softness loss. A goal achieved after three years of work, told Knight: «The first challenge we had to achieve was how do you measure stiffness of the tissue paper, it is a new way to working at stiffness of fibres».

Hercobond 7550EU dry strength resin emerged from the development programme represents the disruption of the paradigm, according to Solenis’ representative, as it proved able to provide strength without impacting softness. «The benefit is that it is mildly cationic. One of my challenge day to day is adding chemicals that don’t upset the balance of the wet end. I like products that are not strongly cationic, because in many way this gives us other challenges», told Angela Knight while presenting at the Tissue World Milan some case studies about the use of the new product. The charge characteristics of the new products are particularly relevant to preserve the charge balance and to avoid flocculation.

Among other benefits of the Hercobond 7550EU dry strength resin developed by Solenis is the long shelf-life, preventing quality issues, and the possibility to use it under a wide variety of conditions, since it is not affected by pH, water hardness, residual sulphite or high conductivity. «Something else that it is really important is to have a product easy to use, plug-and-play», added Knight while explaining the solution polymer is simple to feed and avoids make-down units. «We also asked R&D to deliver something that works in most systems. We don’t want to ask tissue makers to start making other changes to the machines», said Solenis’ representative.

Reduce refining while improving strength and softness

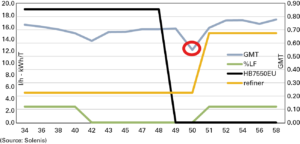

The first case study presented referred to an American light dry crepe machine (45 t/day). The customer objectives were to reduce refining in order to save some money, while maintaining or improving the strength and softness. «The first thing we did was to test dispersability of the Hercobond 7550EU dry strength resin, and there was no negative impact. Using a small amount of product, we got a really good lift in dry strength and one of the refiners can be shut off completely», told Angela Knight. Other benefits included improvement in retention, drainage and clarification (RDC), allowing the machine speed to increase by 75 m/min, and hood temperature reduction, meaning more cost saving. «More importantly, we got a four point improvement in tissue softness hand-feel, measured using the Tissue softness analyzer (TSA)», said Knight. Furthermore, the product allowed for a dosage dependent, 10-20% improvement in Geometric mean tensile (GMT) (figure 1).

A through air dryer (TAD) machine using 100% virgin softwood/eucalyptus blend fibre to produce premium bath tissue was the second case study presented. Here too the final goal was to improve softness through reduced refining. Results are in line with the previous case, with a five point gain in TSA hand-feel and saving of refiner energy of 350 kW, resulting in the shutdown of two of the four refiners. «Another interesting factor is that when you reduce the refining you reduce the amount of fines in the system», added Angela Knight. During the project the fines content in the head box decreased under 10%, while head box freeness increased by 30%. Tissue strength increased by 5-10% even with reduced refining, reported Solenis’ representative.

Yes, it is possible to replace starch

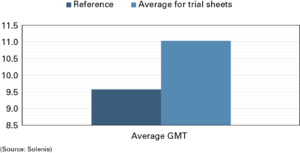

Another case study presented at the Tissue World Milan 2017 referred to the possibility to decrease the quantity of starch (currently 4-6 kg/t) added in the production of towels made of a 50% mixture softwood/hardwood. «Powdered starch is very difficult to replace from a cost perspective. We found we could replace around 4 kg/t dry starch with 1,65 kg/t dry of the Hercobond 7550EU dry strength resin. The retention also greatly improved, up to 73-85%», told Knight. Other benefits included also the improvement of the system charge and the reduction of hood temperature. Wet strength resin addition was reduced by 20%, while tensile resulted maintained (figure 2). «The product run really very well on this machine, with no breaks in 15 hours of running», added the Platform manager.

Achieve the correct wet strength

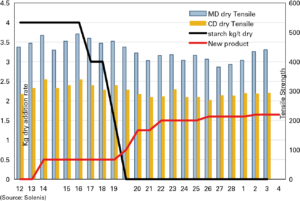

This was the target of another case study presented by Angela Knight, where an Asian-Pacific customer was unable to achieve a wet strength of 120 N/m on exporting towel and napkin tissue grades. The current production ranged at approx. 95 N/m. Solenis’ Hercobond 7550EU was added to the blending chest and tested at different dosages, resulting in the optimum of 1.5 kg/t. The results matched the target value, and also sheet surface smoothness improved, while the machine maintained a stable runnability (figure 3). «Both on this case study and the previous ones, we saw a very good synergistic effect between the new product and wet strength resins. This is sometimes unusual: if you are using a cationic dry strength, the two products tends to compete with each other. While you are going to get a really good dry strength, you lose something of the wet strength», said Angela Knight.

Eliminate softwood fibre

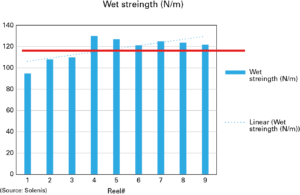

The final case presented by Angela Knight referred to the reduction or elimination of softwood fibre content in the bath tissue of a Light dry crepe machine using virgin fibre. The customer already tried to use enzymes but was not able to eliminate softwood to less than 12%. The addition of the Hercobond 7550EU dry strength resin to the mixing chest allowed to reach the objective, whilst maintaining dry tensile within specification. The loss in dry tensile occurring upon stopping the addition of the product was only regained by reintroducing the softwood at 12% (figure 4). The project allowed for a cost saving on fibre by approx. €15-18/tonnes of tissue produced. Also the cost for electricity decreased by € 0,25/tonnes of tissue produced. The overall treatment cost was reduced by approx. € 5-10/tonnes of tissue produced.