Sensational title for this article, perfect to summarize the last project completed by New Aerodinamica team in Greece. A work that closes the circle of a project started of 2019 for Cartontec a leading company in the paper industry specialized in the production of corrugated board, cartons and other packaging materials in cardboard.

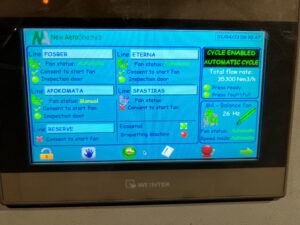

New Aerodinamica got hired to create four suction lines or corrugator, a line of converting, a shredder and a die that conveyed in a new system of discharge with the separator. «We had to stop due to the upcoming pandemic, – explains Paolo Radaelli, New Aerodinamica CEO – but we succeeded in realizing the project in 2020 thanks to a careful and detailed assembly, performed directly by the customer himself with the support of a special remote tutoring implemented by our team. It has been a real success, also driven by the remote testing and starting of the machine conducted directly from our Italian headquarters thanks to a technological upgrade developed in the last years». With such exceptional results, it was clear and easy to commission to New Aerodinamica the realization of a filter dust collector – previously optioned- to make the existing system even more performing. Then, at the end of 2022, thanks to the total recovery of post-pandemic travels, New Aerodinamica was able to go directly in the field to carry out the surveys and select the area of installation for the new machinery. Subsequently, we designed the project on paper and then realized the parts of the process until we got to assembly phase, even this time realized by the customer himself supported by slides, images and tutorials developed by Italian technicians which led to the development of mechanical, electrical and pneumatic parts. This was also made easier by improving the interconnection, following an update on the electrical panel, previously installed, with PLC, touchscreen and remote connection.

The Bergamo team did all the testing, which took place on side on just a weekend: arrival on Friday, first checks on Saturday, tests on Sunday and on Monday the real start with the materials. New filter outcome? Absolutely great, with a super enthusiast customer. The satisfaction was especially due to the great utility of the filter – placed at the exit of the separator- able to suck all the dust, filter it and then come back into circulation of cleaner air. How is it possible to check the real level of air cleaning? It gets simple thanks to the design of a triboelectric probe that contains the continuous monitoring of emissions. That’s a fundamental check, as in case of losses or anomalies the probe launches an alarm and it gets easy to intervene promptly. The plant currently manages 60.000m3/h of waste, involving both the four previously installed lines and reserve couple lines to be developed in the upcoming years. Any environmentally friendly notes? When discharging the filter -given the volumes of air and the amount of dust emitted- there is a briquetting machine that compacts the dust, granting a quick and efficient disposal, resulting in total filter cleaning and elimination of dirt and pollution in the external area of the building. For a tangible and immediate result and a very high level of… pure satisfaction, as confirmed by the client: «In order to complete our suction system we had no other choice but to recontact New Aerodimanica because we were sure that the new realization will was as successful as the previous due to high equipment quality and high professionalism of New Aerodinamica staff. Now our suction system is complete and is working continuously without any problems providing our company high productivity of our converting machines and corrugator, clean production spaces without any dust or waste paper. The maintenance cost or suction system is very low.For all that reason we recommend New Aerodinamica as a reliable partner.»