The Biocompack CE project, funded by the Interreg Central Europe (2014-2020) programme, brings together the world of paper and the world of plastics. The aim is produce multimaterials to be used, in particular, in the packaging sector, to meet the new needs of the customers in terms of functionality.

The use of multimaterials is cross-cutting to several supply chains, even the ones that are historically considered to be on opposite sides, like the paper and plastics Though different, the two supply chains still have complementary elements, which, through innovation, can lead to the development of new materials. Biopolymers are generated exactly from this encounter. To favour the introduction on the market of biopolymer-based products with lower environmental impacts, the European project Biocompack CE was launched in mid-2017, involving countries from central and Eastern Europe: Poland, Hungary, Slovakia, Slovenia, Croatia and Northern Italy. The project is framed within, and is financed by, the Interreg Central Europe (2014-2020) Programme www.interreg-central.eu.

Collaboration for innovation

In Italy, Biocompack CE was christened by Innovhub and Legambiente, i.e. project partners together with other European organizations, which officially kicked off the project for Italy at the end of November in Milan. «The aim of Biocompack CE», said Graziano Elegir, who is in charge of the chemical and environment unit of the Innovahub Milano paper division on the occasion of the project kick-off meeting, «is to promote the introduction of biopolymers both as films and as solutions that can be added to paper-based products, in order to achieve lower environmental impacts, thereby reducing the use of non-biodegradable microplastics and thus their presence in the recycling processes; favour solutions based on renewable sources of energy; improve the organic recycling processes and thus compostability; and improve, or at least not undermine recyclability in the paper supply chain. The programme foresees forms of collaboration aimed at innovation, in order to enhance the competitiveness of the European region involved and, more specifically, increase the connections between the players involved in innovation system, i.e. the paper and plastic supply chains, which are to be intended as a single supply chain for the purposes of this project».

Paper and bioplastics have, after all, several elements in common: they are biodegradable, stem from natural materials, are renewable and recyclable. «These are two competing materials», says Assocarta Deputy Director-General Massimo Ramunni, who participated in the event, «for example, when it comes to raw materials – also in the paper sector work is being made to produce papers starting from food industry waste – and applications, however there are several possible synergies, because of the very common values linking paper and bioplastics. We therefore welcome this project, which is capable of inducing a capital intensive industry, like the paper sector, to move towards this direction and innovate». Massimo Ramunni highlighted that sustainability is the fundamental prerequisite in this respect, whereby it should not only be intended as environmental sustainability, but rather as sustainability linked to economic and social aspects, too.

The Biocompack CE project stems from the union of two previous projects and the relevant competences developed: Ecopaperloop, which was coordinated by Innovhub, and Plastice CE, which was coordinated by the Slovenian Chemical Institute.

Paper & bioplastics

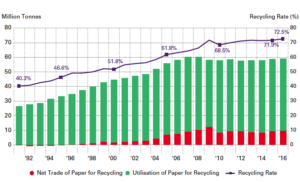

Paper and bioplastics, are thus suitable for the production of sustainable packaging. «Paper has a high degree of recyclability thanks to mechanical recycling and can be composted, provided it was not added products that might hamper its compostability», continued Elegir. «In Europe, in particular, recycling has increased from 40% in the 1990s to a current average percentage of over 70% (figure 1). It is worth pointing out that in the paper sector 80% is considered the natural limit for the recycling of paper, and this might explain why figures have not grown considerably in recent years. In some countries, this limit has been reached; in Italy, for instance, the recycling percentage is even higher, if one takes packaging alone into account. The European average is about 60 million tons of collected material, with a recycling rate over 50% at a European and world level».

Bioplastics can, instead, be recycled organically through composting. «Five categories can be identified: bioplastics coming from renewable sources, which are not, however, biodegradable and compostable; bioplastics from oil sources, yet made biodegradable thanks to some chemical properties; and finally the bioplastics covered by the project, which stems from renewable and biodegradable sources, like PLA or and polylactic acid».

Multimaterials pose more difficulties, as their degree of recyclability depends, on the one hand, on their often complex composition, which has to be carefully analysed in each individual case, and on the other on the use they are destined to. Design is another important element to consider for recycling. Design should take the packaging material end-of-life since the beginning into account. According to Elegir, «this is possible thanks to the technical-scientific knowledge of materials, the use of scientific methods and the application of technical standards that are recognized by the supply chain and set the rules for the certification of products».

At the level of norms, reference legislation is provided by the EU Waste Packaging Directive 94/62 and voluntary environmental certifications. No technical international standard regulates paper recyclability. However, the EN 646 standard on the list of commercial recycling papers and EN 13430 with general indications can be applied. «The Ecopaperloop project was a first attempt to propose an international standard, which however was not accepted at European level. In Italy, conversely, the Aticelca MC 501-2017 method on the recyclability of mainly paper-based products was defined» (figure 2).

The beginning and the end

Paper recycling system is a complex, but already well-established system, «there are very large volumes at stake, which guarantee the very survival of the paper industry», said Ramunni. «Waste paper accounts for nearly 60% of the raw material used, therefore attention to its quality is a priority issue». When recycled raw materials made of polycoupled materials are introduced in the paper making process, plastics must be separated from fibres. «This is a procedure, which is technically certainly not simple and reduces the process output because of a reduction of the recovered material. The material separation could be carried before the raw materials enter the paper mill, i.e. by citizens or the recovery platform», yet this would require a raw materials planning activity that makes the whole process easy and possible.

Another issue to deal with is the use of process waste, which is made of a mix of different plastic materials. While there are already several projects analysing ways to recover this waste to obtain recycled plastics, the use of bioplastics could change the scenario; yet, if bioplastics are introduced in the paper making process it is worth understanding how the process is impacted by the use of bioplastics. Another possibility is the composting of bioplastic waste, yet this is not the ideal solution, too, as Ramunni explained: «Paper fibres can be recovered and used again to produce other paper; a hierarchy based on use should therefore be respected. Paper should be recycled as long as fibres keep their capacity to make links to generate a sheet of paper, to then be composted only if it turns out that it is excessively degraded».

Waste paper

As regards the relation between compost and paper, in Italy a framework programme was signed between the Italian Consortium of Composters CIC (Consorzio Italiano Compostatori) and Comieco, i.e. the National Consortium for the recovery and recycling of cellulose-based packaging. The framework programme saw the start of a technical collaboration from 2013 http://bit.ly/2fi8ant. Product surveys have been carried out on different types of paper, with the aim of categorizing the forms of paper packaging present in organic waste; the final objective was to determine what type of paper ends up in the organic fraction of municipal solid waste and why consumers throw it away as organic MSW.

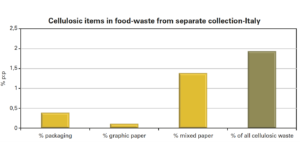

For each type of paper, the corresponding presence in the compost chain was quantified and the possible links between the presence of paper and total non compostable materials were investigated. It emerged from the surveys that tissue paper is more prevalent, followed by cellulose-based packaging and graphic paper to a negligible extent (figure 3).

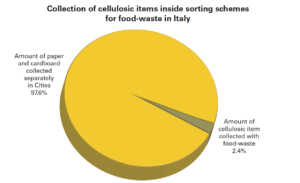

These are very low numbers, though, as stated by the coordinator of the CIC Technical Committee Alberto Confalonieri. If one considers the total quantity of waste from separate collection, they account for 2.4%, i.e. over 73 thousand tons of paper compared to about 3 million tons of paper collected by municipalities (figure 4).

«Neither negligence, nor the lack of correlation can basically be highlighted when it comes to starting the production of paper and cardboard products in the organic supply chain with more sustainable behaviours. This has made us collaborate with Comieco for the classification of different types of paper products when it comes to possibility for them to be accepted in the organic supply chain, which also has to go hand in hand with a compatible collection system». Making certain products compostable namely implies the need to redesign both the paper and cardboard, with which they are made, and the equipment, with which they are collected, as this equipment has be fit to accommodate them, starting from the containers for the wet fraction.

Plastics & Co.

A large quantity of materials present in the wet fraction is represented by plastics, especially flexible plastics. The analysis of the waste wet fraction carried out by CIC in 2017 show the presence of 93.7% of organic waste, 1.4% of bioplastic packaging, 3.1% of plastic packaging and a remaining 1.8% of other non compostable materials. Specifically, this includes 60,1% of flexible conventional plastics, mainly plastic bags, 31.7% of bioplastics and 8.2% of rigid plastics.

«The issue of replacing plastic food packaging with bioplastic ones is a major one», explained Confalonieri, «both because it improves the quality of the waste being composted by reducing the so-called “drag” effect, which induces to sacrifice part of the compostable material when eliminating wrongly separated non-compostable materials, and because the use of compostable bags for the humid waste collection leads users to adopt sustainable behaviours in selecting the waste to through in these bags».

Greenlight to business

Biocompack CE is a technology transfer project involving expert bodies and companies at various steps of the supply chain. Because of this, the project also foresees a Business support service, whose task is to help companies discover the business opportunities related to the world of multimaterials. During the year a pilot phase will be started, during which a number of selected companies will test the business support service, to then enter the last phase of the the project with the establishment of a Transnational biocomposite centre to support innovation in the sector of coupled paper-plastics multimaterials. The project will ultimately enable to create a network of various skills, which includes the supply chains involved, universities, research centres, labs, etc., that companies can apply to in order to be supported in the creation of products made from multimaterials.