A wide number of issues is commonly to be taken into account in order to design an efficient and suitable load calibration strategy. When it comes to Yankees, in fact, many critical factors must be considered. The Calibrated Press Load range of services and solutions comes alongside with a Yankee modernisation process.

by Roberto Carminati

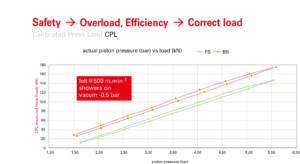

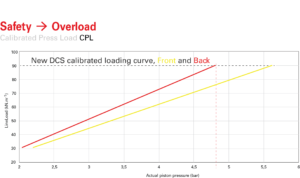

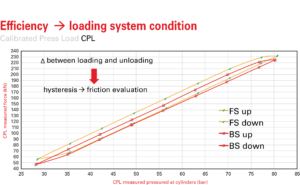

Following his presentation at Tissue World, Mark Penton, a technical services manager at German based Msquared, underlined which, in his view, were the most important aspects of such an event. In an interview, Penton pointed out how crucial it is to talk to new generations of operators in such a conservative environment as the paper and tissue industry sometimes is. But furthermore he added that the company had the chance, in Milan, to offer a broad overview of its portfolio of products and services, that nowadays also include the Calibrated Press Load solutions family. «Applying the right load force to the pressure rolls to obtain the correct line load», as Msquared itself reported, «is foremost a safety requirement. However, uniform mechanical dewatering requires also a known and balanced load to the press, for instance, and this both directly impacts safety; and strongly affects a machine’s efficiency». As the supplier – that was recently acquired by the Jäger Group, also prominently devoted to the paper and tissue segments – explained, «Calibrated Press Load is an Msquared re-developed and renewed system for measuring the real and effective pressure roll loading force in relation to a hydraulic or pneumatic pressure». The aforementioned system builds on «calibrated force and pressure sensing components in order to establish calibration curves for the front-side and back-side press loading mechanisms». Reports continue by observing that «in addition, comparisons to the DCS (Distributed control system) calculated and/or indicated load and actual loads, indicated pressure and actual pressures are all established». Finally, Msquared stressed that «loading and unloading hysteresis curves are established; and these parameters indicates the effectiveness and the overall condition of the loading mechanism».

A critical issue

According to Mark Penton, a wide number of issues is commonly to be taken into account in order to design an efficient and suitable load calibration strategy. When it comes to Yankees, in fact, many critical factors must be considered. Penton’s opinion is that operators should be «very cautious» in verifying that the Yankee is not overloaded, since it shows rather frail and «easy to deteriorate» especially in case its loads are not correctly balanced. Under these circumstances, as the technical services manager commented, one of the major risks is to reduce drying efficiency, which results in additional burdens that tissue manufacturers should bear. A mere 1% less humidification, according to Mark Penton, «translates into a 4% energy saving», that represents undoubtedly a significant figure. The Calibrated Press Load range of services and solutions became a part of Msquared and Jäger’s catalogue only recently, as it became clear that, in Penton’s words, only a small number of clients were adopting targeted strategies in order to measure their press loads. The proposition comes alongside with a Yankee modernisation process, which is most meaningful because, so far, the sector has proven relatively slow and cautious in innovating. Load and fatigue limits also regard the new generations of steel Yankees and this could generate «potentially catastrophic events» of which Mark Penton has a direct experience. He explained in fact, in an interview to Tissue World TV, that he had the chance to assist to authentic explosions, and this is one of the reasons why he believes that load monitoring and measurement operations are «essential», when paper producing companies aim to avoid these most dramatic and dangerous accidents.

A complete portfolio of services

Together with the newly launched Calibrated Press Load monitoring offer, Msquared can also provide its worldwide customers with a well-established portfolio of services, especially addressed to the paper industry’s typical drying systems. The proposition can be split into three different categories, representing some of the most outstanding aspects of condition monitoring. The company itself states that tests are carried out independently, with no links or forms of cooperation with other Original equipment manufacturers, or Oem, specialised service companies or suppliers, therefore fulfilling the promise of a complete integrity of data. The first aspect identifies with Condition Assessment Production, also referred to as CAP, to optimize the runnability of the Yankee in the overall tissue machine system. Diagnostic tools are On-the-Run Topography-TNG and IRSense – Infrared Temperature Mapping and relevant services are targeted to mill production staffs. Condition Assessment Maintenance (CAM) is then used «to predict the necessary maintenance actions and intervals for re-conditioning the Yankee». Diagnostic tools are, in this circumstance, grouped under the LMS – Laser Surface Mapping brand; whereas «these services are targeted to mill maintenance staffs».

Finally, the Condition Assessment Safety (CAS) strategy aims to conduct the necessary routine and non-routine vessel inspections according to Tappi (the Technical association of pulp & paper industry) guidelines, local statutory and/or insurance requirements. Diagnostic tools are standard NDT (an acronym indicating Non-destructive tests) equipment, and the aforementioned services are targeted to mill safety engineers. «The ability to offer and to conduct the complete CAP + CAM + CAS package, backed up using state of the art specialized diagnostic tools, together with many years of experience for recommending corrective actions», as Msquared reported, «make this service really unique». Building upon its expertise, the German supplier can also provide customers with general consulting services, mainly addressed to the issues of drying cylinders, and comprehensive of inspections, maintenance, redesign and rebuild of these complex structures. A part of this specific offering deals with the optimisation of crowning systems, both cylinders and presses, considered as «critical for producing a uniform cross machine direction profile, in moisture and many other sheet properties». The provider has developed a series of diagnostic tools in this field, as well as in the area of Yankees. In fact, «Yankee/Mg dryer safety management programs are essential for the operation of pressure vessels» and therefore Msquared states it can «help customers to set up or audit an existing safety management program for drying cylinders». General problem solving and troubleshooting, most of all targeted to cylinders «that display drying issues or have high wear rates» (frequent grinds, for instance) are also a part of the firm’s offering; determining «a path forward for cylinders problems».