While shoe presses have been around for decades, their application for tissue production was introduced in the late 1990s. Andritz was one of the pioneers in this development work for the tissue segment. Based on 14 years of experience, Andritz has developed a completely new shoe press concept, the PrimePress XT Evo. This type of shoe press helps tissue makers to remarkably reduce energy consumption in combination with a broad flexibility in production (grades and quality) to meet the different market requirements. It gently dewaters the web, achieving a far higher post-press dryness and sheet bulk than conventional pressing.

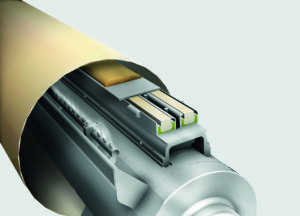

The thin and flexible shoe, in combination with an innovative loading system, “follows” the contour of the Yankee shell alongside the machine width, thus allowing a uniform nip in a large range of line loads between the shoe press and the Yankee. Due its flexibility the shoe is able to adapt to the dryer cylinder, but is sufficiently stiff to achieve the required nip pressure profiles. The line load and the pressing profile can be easily adjusted during operation from 70 to 150 kN/m, without any need of crowning compensation for an even press load. The machine direction pressing profile is monitored online and shown in the control system.

A real highlight of this press concept is the edge control system. In the edge area the local lineload can be controlled and the optimum press nip can be set. The flexible shoe, in combination with the individual control of the edge zones enables: compensation of edge issues, compensation of crown issues, setting of customized optimum press nip conditions at the edges.