For some people it is simply a marketing strategy to attract even the most tireless champions of our planet; for others it is an inevitable choice. Regardless of their opinion, manufacturing paper using natural fibres from waste of agro-food by-products, seaweed, milk and even marijuana is not that bad, is it? Less waste to burn, more respect for the environment.

by Titti Cocola

A few years ago, some paper mills made the first tentative attempts to launch innovative papers with alternative fibres to partially replace cellulose. The initial papers were immediately successful confirming that there is greater interest among consumers in buying environmentally sustainable products. Today, many different papers are available and brands can find innovative solutions that respect the environment at the same time.

The rebirth of agri-food waste

Recycling is imperative. And so is recycling! Nothing could be easier, particularly if turning to the agri-food industry that, although re-using agro-industrial by-products in animal husbandry, energy and cosmetic products, still incinerates huge quantities of by-products. And this is where some paper mills come in with some truly surprising products.

Paperwise’ Socially Useful Paper

This is an ambitious project launched by the Paperwise paper mill to manufacture environmentally sustainable paper using Indian and Colombian paper mills by investing in training and equipment to ensure the development of local communities.

This idea has come from Peter van Rosmalen, the Dutch CEO of Paperwise, who in January 2015, after 16 years of experience as distributor of paper decided to set up his own business. After two years of working with local businesses, the manufacturing of papers and paperboards is finally ready to be marketed in Europe..

But what’s in Paperwise paper? Stalks and leaves left in fields after cutting wheat or in trees following fruit harvesting. These by-products are partially used as sources of alternative energy but, in most cases, they are burned. The paper mill manufacturing graphic paper is in Kagithapuram in southern India. This was not a casual choice. It was made because this company is close to a multitude of fields that can provide sufficient quantities of raw material to the paper mill all year round.

The Indian paper mill only uses river water. It does not use ground water because it could damage local farmers. From the energy point of view, the factory can rely on a wind farm and its own power station generating steam energy. The paper is then shipped from India to Rotterdam in cargo ships with an A or B Energy Label.

Favini Transforms Waste into Innovative Packaging

The Favini Crush range does not need any introductions. Based in Rossano Veneto, in the Veneto region of Italy, the paper mill re-uses agro-food by-products (coffee, hazelnuts, almonds, citrus fruit, kiwi, olives, corn, lavender, cherries and, more recently, grapes) to manufacture papers with a high level of creativity, an FSC certificate, no GMOs and 30% post-consumer recycled content made with 100% green energy using a patented manufacturing process.

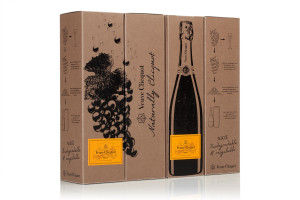

The very first partnership was with Barilla for which Favini has created Cartacrusca. The most recent partnership has been between this paper mill Veuve Cliquot and DS Smith and has led to the Naturally Clicquot 3 packaging. This packaging is manufactured with 100% biodegradable paperboard obtained by creatively re-using some by-products of the champagne production process.

Pedon, a company based near Vicenza in Italy and one of the major international players in the cereal, pulse and seed industry, has followed suit and gives its waste to Favini. Pedon has contributed to create Crush Fagiolo, which is 100% recyclable and is used for food packaging. This is the very first paper that is suitable for primary packaging as it is in direct contact with food.

Restalk, Cannabis for Packaging, and Nothing Else!

Legalisation of cannabis for medical reasons has contributed to the proliferation of guaranteed crops that produce huge quantities of waste as is the case for all other crops. Heaps of processed stalks turned into sludge have been the reason why Restalk LLC was set up. Last February the company launched its first prototype and will soon start commercial production. Headed by Lucas Hildebrand, who is also a co-founder, Restalk acquires its supplies from Emerald Family Farms, a farmers’ collective based in northern California, a regiona considered the “legal” capital of marijuana for the western hemisphere.

Starting from next summer, a small run for packaging applications ought to be available. Should demand increase, the company is ready to step up its production.

Restalk LLC is fully recyclable: no toxic material is added; it only has waste material. Tests are currently being carried out to find out whether this paper can be used with other materials.

LeafLAB and GTea: Primary and Secondary Packaging from Cocoa, Coffee and Tea

LefLAB is the ambitious project of Schweitzer-Mauduit International, a historic American business with a valuable know-how in fibre engineering and extraction. The project is the outcome of a diversification and expansion process of its product portfolio that is mainly focused on the tobacco industry.

LeafLAB aims at introducing a series of innovations based on vegetable fibres mainly designed for the drink, cosmetics and packaging industries. As far as the packaging industry is concerned, the newly formed company has a two-fold objective: (a) supplying paper mills with vegetable fibres from cocoa, coffee and tea by-products that have been processed and are ready to be used to manufacture paper; and (b) selling paper on demand using vegetable fibres provided by customers in the paste. Cocoa Paper, Tea Paper and Coffee Paper are multi-sensory papers used for primary and secondary packaging of food. “We are ready to manufacture paper from cocoa shells – says Julien Floch, LeafLAB Marketing Manager – whereas we are still testing paper from by-products of coffee and tea leaves and we are doing quite well.” As far as grammage is concerned, the paper mill is in a position to manufacture between 70 to 100 grams in-house. However, thanks to a group of partners who are working together with the paper mill, paperboard up to 250 g/m2 can be manufactured. Shades, explains Julien Floch, basically depend on the proportion between vegetable and virgin fibres that can reach a 90 to 10 ratio. Manufacturing these new brands and virgin fibres will be mainly carried out by two plants: the one in Le Mans, France, where the company European headquarters are based, and the other one in Ancram, in the State of New York. Cocoa Paper is suitable for direct contact with food and is the first natural paper specifically designed for chocolate products and their packaging.

Goglio Gtea is a new material created to come into contact with food. It can absorb radicals and acts as an antioxidant. This means that packaged food lasts longer and, at the same time, its flavour, aroma and scent stay unchanged. This is an important challenge for the Italian company, leader in the field of flexible packaging and packaging equipment. As well as concentrating on the technical and scientific aspects of this project, the company has also focused on the ecological peculiarities of the product itself. The substances used in the GTea packaging, i.e., 100% natural antiradicals, come from the catechins in green tea.

The adhesive called Goglio GTea and the packaging where it is used are ideal to package any dry and powder product, or any product in pieces with or without preserving liquid.

Papermilk, Nourishment for Creativity

This idea came from Susanna Bonati, a very creative person from Milan, one and a half years ago after expanding her knowledge of milk products whose market share in the fashion world is becoming increasingly significant. Papermilk contains milk fibres that give base papers unique texture and softness. It also means and immediate recollection of the primordial and vital need for breast milk which “protected’ and nourished us like no other thing. The paper manufactured by Cartiera di Cordenons, contains cotton linters and pure virgin cellulose fibres from responsibly managed sources.

Alge: Harmful for the Environment, Precious for Paper

At the beginning was Alga Carta. Launched in the 1990s by the Favini paper mill to solve the problem of the proliferation of seaweed in the Venice lagoon, this project has led to the creation of the Shiro environmentally friendly papers and the lodging of an industrial patent still owned by the Rossano Veneto-based mill.

The powder obtained from collecting, drying and grinding seaweed to use in the manufacturing process has meant that Favini is still in a position to replace one kg. of tree with half a kg. of fresh seaweed to manufacture environmentally friendly paper. This is how a high-quality base paper is produced. Thanks to the chlorophyll in the particles of seaweed that can be seen on the surface, over time the paper becomes whiter.

This is a paper that intrigued Voya, an Irish company manufacturing organic beauty products that has based its success on developing natural products from processed seaweed. Voya has worked with the Italian paper mill to create its own special paperboard to restyle its coordinated image and for its new packaging project, both handled by Dynamo, a creative design agency. Thanks to the partnership between Favini’s R&D Division and Premier Paper Ltd., a European distributor, a base paper manufactured with the by-products from the production of cosmetics of the Irish company and the FSC-certified cellulose pulp normally used by Voya has been developed. This way the company has managed to reduce its environmental footprint that was the project’s main objective.