The age of generalist middle-sized paper mills is over. Those which survive are only large consolidated groups and small businesses working in niche sectors, which sometimes also manage to prosper thanks to investments in equipment and new products. This is the case of Gruppo Cordenons: we have tried to grasp the secrets of this all Italian success story.

Against the backdrop of a distressed European scenario for the paper industry, one can luckily register notable exceptions from a consolidated trend, which shows the closure of paper mills established in past centuries and the survival of very few new installations. These exceptions include an Italian business, whose origins date back no less than to the 17th century. This is Gruppo Cordenons, which boasts two production plants in the North-East of Italy, 280 employees and a turnover of 78 million Euros and can thus be considered a relatively small group in the paper industry. Yet it has «critical mass» and the right products and dynamism necessary to affirm itself in a context, in which only very large groups and paper mills specialized in niche products can survive. It is not only affirming itself – it is rather prospering, as the turnover of Gruppo Cordenons increased by twelve percentage points in 2014 compared to the previous year and the company has the financial capacity (and the entrepreneurial courage to invest several millions Euro in technologies and the renewal of its installations this year. So, what’s the secret? It has always aimed to be the leading company for special papers, ranging from the tactile ones that feel like plastic at the touch to the metal papers, from the classical marked papers to the embossed and laid ones.

History

Led by Ferruccio Gilberti, Gruppo Cordenons has two plants, where it produces over 2,500 special products for specific targets and applications (i.e. mainly fine and technical papers) for a total of 35,000 tons per year. One plant lies in Cordenons, in the province of Pordenone, while the other is situated in Scurelle in the province of Trento. As already mentioned, the origin of these two paper mills date back to a far-away past. The Cordenons mill was the property of the Avanzo Counts from Cordenons from 1630. In 1730 it was then transferred to the local family of entrepreneurs Galvani. The citations by the Council of the Dogi about the importance of the «Cartera de Cordenon», i.e. the Cordenons paper mill, which was the official supplier of the Venetian Republic, date back to this period. In 1984 the paper mill and its facilities were completely renewed, although its focus on high-quality special papers was maintained. The Cordenons plant accommodates two paper machines equipped with a line IT control system, which produces 160 cm wide paper rolls. The rolls mainly differentiate for their coat weights ranging from 60 to 1,500 g/m2. The plant also accommodates two off-line coating machines, which are equipped with an automated control system, four cutters, six embossing machines, one cutter and two automatic packing machines.

Let us now move on to the Scurelle paper mill. Established in 1715, still today it produces special papers with a 160 cm long paper machine, which is equipped with an IT line control system and can print papers with coat weights ranging from 70 to 400 g/m2. A cutter completes Scurelle equipment.

The right niche

As mentioned earlier, Gruppo Cordenons is still growing in terms of turnover, but also in terms of both gross operating margin, which grew by 45% (+13.5% of turnover) in 2014 compared to 2013 and net cash flow (+60%). These results made it possible to plan investments in technology and installations modernization of 5.5 million Euro (3.5 million of which for the new energy installation) in 2015.

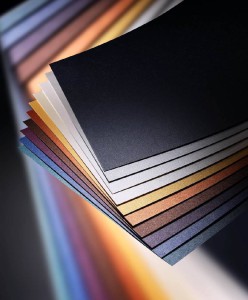

These results are mainly to be ascribed to the fact that the company has always focused on special papers, as well as fine and technical papers, ranging from the metal and iridescent papers to the most innovative ones with special effects that recall the tactile and visual feelings of plastics and fashionable fabrics, up to the most classical, marked, laid and embossed papers.

And the results are also due to the fact that the company has invested considerable amounts of money in “tailor-made papers” to meet the needs of increasingly demanding customers. Leading luxury brands are the main uses of these papers and paper boards that they use for packaging, shopping bags or communication material, thereby turning them into integral components of the image of their product.

As Gruppo Cordenons central technical manager Giorgio Monacelli puts it, «our secret lies in supplying to designer fashion labels, which would never choose banal supports for the package of their perfumes or foulard scarves. The fact that we have a major research and development department and carry out the finishing operations on our papers internally, like embossing or coating, makes it possible for us to create papers that are tailor-made to the needs of our customers. It is exactly this peculiarity that enables us to grow in a difficult market, where only very large commodity groups and highly specialized businesses like ours seem to have room to grow. It is not by chance that middle-sized paper mills are gradually disappearing in Europe».

The ability to innovate

A company like this, which has specialized in special papers and is constantly asked for the latest paper supports capable to amaze and stand out also in terms of the printed product, cannot therefore rest on its laurels. As the marketing manager of Gruppo Cordenons Katia Tedeschi tells us, «every year we finalize and bring to the market a couple of new products, which normally come from our internal research and development department or the input of our customers. The latest special paper born is the Papermilk tactile paper, which is produced with milk fibres, cotton linter and fibres of pure virgin cellulose». Papermilk is the brainchild of the Italian creative artist Susanna Bonati and has been produced in collaboration with Cordenons Spa. This paper stands out for its softness and very pleasant velvety effect. It is ideal for offset printing, thermography, hot printing (with or without foil), dry relief printing, typography and laser printing.

The FSC certified Papermilk comes in the 72×102 cm size and 140, 250 and 350 g/m2 coat weights.

The LuxePack event held in Monaco last October was the occasion to present a new brochure of the Natural Evolution range, which features the new Natural Evolution Recy paper. The Recy version contains 30% FSC certified recycled fibres and differs in colour from Ivory and White thanks to a more natural shade of white that is between the two. As Mrs Tedeschi points out, «Papermilk, Natural Evolution Recy and all the papers of Gruppo Cordenons are the result of accurate research to identify the needs of the customers and the environment. The efforts in favour of environmental protection stem from the awareness that the environmental performance of a product has to be assessed in more general terms and not only from the small and confined point of view of the sector. Hence the use of milk fibres, cotton linters, recycled fibres, pure virgin cellulose fibres, major investments and attention to market needs, combined to unique production capacities».

Successful papers

If Papermilk is the newborn paper at Cordenons, the business inventiveness is shown by two other historical products of this Italian company: Stardream and Plike. The name stems from the abbreviation of the Plastic and Like (PLike) words and refers to papers and paper boards made of virgin cellulose fibres, which are dyed at the pulp stage and coated on one or both sides with a special product developed thanks to the know-how of Gruppo Cordenons, which provides for a plastic-style surface at the sight and touch. Applications range from luxury packaging, to prestige editions of wishes and business cards. The surface features however a very modest absorption that is why oxidizing inks should be used in offset printing, with the adding of a drying agent when working with rather high ink loads.

Yet another flagship of the company is the well-established Stardream line, which like most Cordenons papers is FSC certified. The line features papers and paper boards made up of (Elementary Chlorine Free) virgin cellulose fibres which are dyed at the pulp and finely coated with pearlescent pigments. The main feature of this paper is its multicolour surface with mother-of-pear, metal, iridescent or changeable effects, which changes its predominant colour depending from the observation angle. The paper comes in smooth and embossed version or in versions for HP Indigo and laser printing in general. An amused Katia Tedeschi concludes by saying that «we have been among the very first in the world to produce a metal paper and launch it on Asian markets so much that all similar products made by other paper producers following our path were referred to with the name of our paper».

[metaslider id=1520]