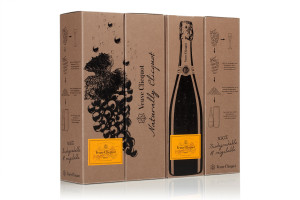

It is not just words: from Favini two ideas which have improved its catalogue of papers made from food waste. The first is called Naturally Clicquot 3, a new 100% biodegradable and recyclable packaging, which brings together innovation and elegance, produced in collaboration with Veuve Clicquot and Ds Smith: support which originates from the creative re-use of by-products of the production process for Veuve Clicquot champagne. In full respect of the environment, after the pressing of the grapes, the grape skins find a new use. Thanks to the know-how of Favini in creating paper obtained from agro-industrial residue, the skins are dried and micronised to become raw material for the production of a unique ecological paper, saving 25% of virgin fibres.

And to obtain the innovative paper used for the ecological packaging of Veuve Clicquot, Favini puts the residue into the manufacturing cycle, mixing it with water and natural fibres, replacing part of the cellulose.

The second idea comes from the collaboration with Pedon, an Italian company in Vicenza specialising in the cereals, legumes and seeds sector, linked by green philosophy and respect for the environment. It is called Crush Fagiolo, and is the first paper obtained from the waste from processing beans, 100% recyclable and destined for food packaging, certified for direct contact with food.

The creation of this new ecological paper falls within the ethical project Save the Waste, promoted by Pedon, which supports the culture of business responsibility, from the producer to the consumer, guaranteeing the selection of non GM seeds cultivated by thousands of families of farmers within economic and agricultural development programmes.

Crush Fagiolo, indeed, originates from by-products of beans, reducing the use of virgin cellulose from trees by 15% and reducing greenhouse gas emissions by 20%. The result is a GM free, FSC certified, ecological packaging, which includes 30% of post-consumer recycled fibre. Crush Fagiolo is the first paper, created by Favini, suitable for making primary packaging, in direct contact with food: from an ecological point of view, this allows for the avoidance of double packaging and supplies a really eco-friendly solution for reducing the environmental impact of packaging. The packaging developed by Lucaprint was printed with ecological inks and has a transparent PLA window obtained from recovered vegetable waste, which makes the packaging 100% recyclable.